Automation

At Maher, we believe in staying at the forefront of innovation to provide our clients with the best possible manufacturing solutions.

That's why we've made substantial investments in automation technologies to enhance our manufacturing capabilities and, in turn, increase productivity for our valued clients.

Our Automation Arsenal

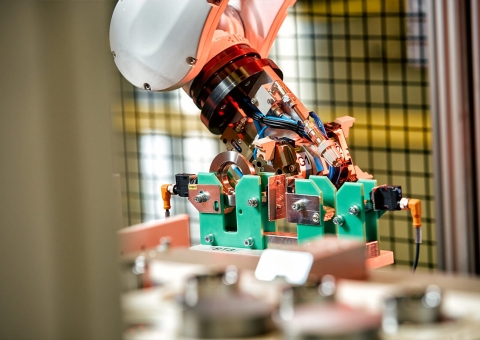

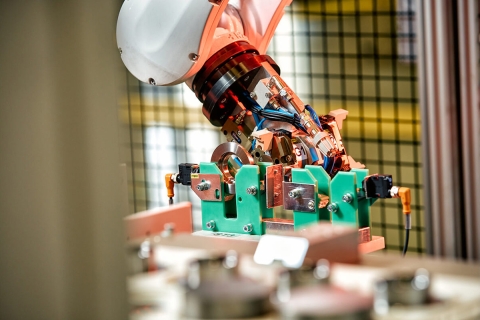

ABB Robot Cell

For our Okuma B300III Mill/Turn CNC Machine, we've employed the cutting-edge ABB FlexLoader FP800 machine tool tending system. This integration features automatic loading and unloading and ensures that our machining processes run efficiently, consistently, and with minimal downtime.

The result: greater productivity for our clients.

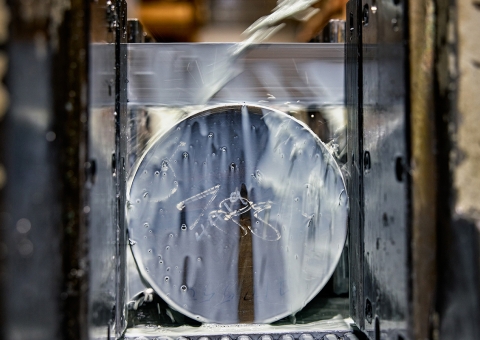

Nachi Robot Cell

To further streamline our manufacturing processes, we've implemented the Nachi MZ25-01 Articulated Robot, which operates in conjunction with our Gantry Fed Okuma LT 2000 Mill/Turn CNC Lathe.

This cell also features integrated Crytal Apex CMM Inspection allowing for the full process to be completed “lights-out” thereby reducing lead times and ensuring high-quality output.

Co-bots with CMM Loading Application

Our commitment to automation continues with our utilisation of Co-bots equipped with Cutting-Edge Coordinate Measuring Machine (CMM) loading applications.

These versatile co-bots work seamlessly alongside our skilled workforce enhancing productivity in our inspection processes.

Our Pledge

Our investments in automation aren't just about embracing the latest technology – they are about delivering tangible benefits to our clients:

Reduced Lead Times

Increased Productivity

Consistent Quality

Embracing the Future

At Maher, we are committed to ongoing investment in automated serial manufacturing. We keep an eye on emerging technologies and constantly seek opportunities to enhance our capabilities.

By choosing Maher as your manufacturing partner, you're not just gaining access to cutting-edge automation; you're partnering with a company dedicated to your success.

WORKING WITH